Gas Valve Replacement Timing

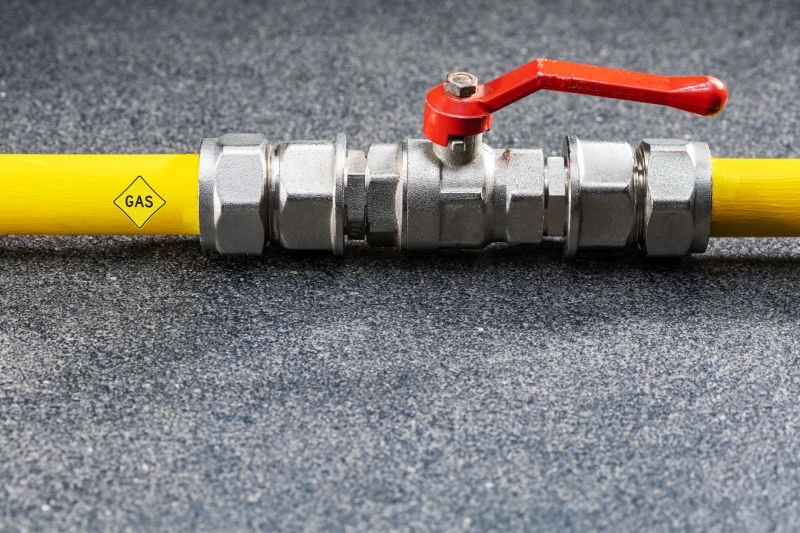

Gas valve replacements are critical for maintaining safe and efficient operation of gas-powered appliances and systems. Timing for replacement depends on factors such as age, usage, and signs of wear. Regular inspections can help identify issues early, preventing potential failures and safety hazards.

Leaking, corrosion, or difficulty regulating gas flow indicate the need for replacement.

Valves over 10-15 years old are more prone to failure and should be evaluated regularly.

Inconsistent appliance performance or frequent shutdowns may signal a worn or failing gas valve.

Replacing gas valves during routine system overhauls ensures safety and efficiency.

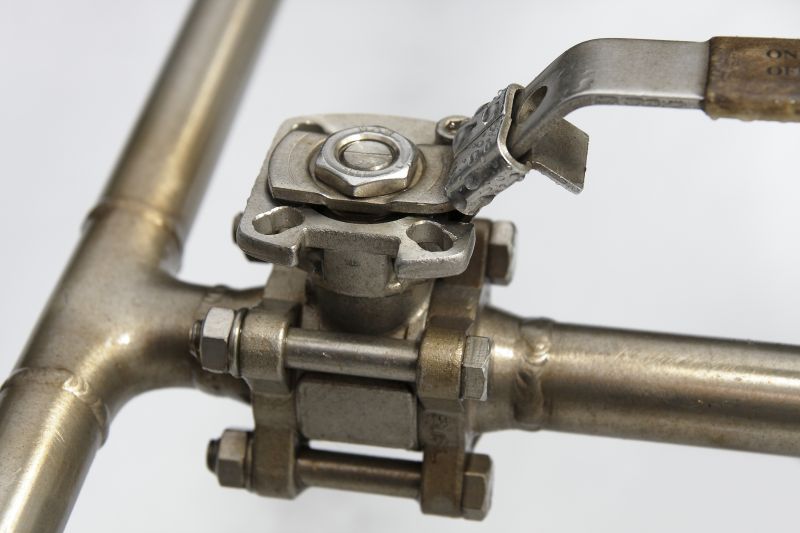

Technicians examine the condition of gas valves for signs of wear.

Corrosion can compromise valve integrity and safety.

Proper installation ensures reliable operation.

Upgrading old valves improves safety and efficiency.

Ways to make Gas Valve Replacements work in tight or awkward layouts.

Popular materials for Gas Valve Replacements and why they hold up over time.

Simple add-ons that improve Gas Valve Replacements without blowing the budget.

High-end options that actually feel worth it for Gas Valve Replacements.

| Factor | Recommended Action |

|---|---|

| Age over 10 years | Evaluate for replacement |

| Signs of leakage or corrosion | Replace immediately |

| Performance issues | Inspect and consider replacement |

| Scheduled system maintenance | Include gas valve check |

| Harsh environmental conditions | Plan for earlier replacement |

Gas valve replacements are essential for maintaining the safety and efficiency of gas systems. Regular assessments and timely replacements can prevent malfunctions, reduce energy costs, and ensure compliance with safety standards. Consulting qualified technicians for inspections and replacements is recommended to ensure proper handling and installation.

Specialized tools facilitate safe and accurate replacements.

Proper fitting ensures reliable operation.

Thorough inspection identifies issues early.

Following safety protocols prevents accidents.

Finishes and colors that play nicely with Gas Valve Replacements.

Little measurements that prevent headaches on Gas Valve Replacements day.

A 60-second routine that keeps Gas Valve Replacements looking new.

A frequent mistake in Gas Valve Replacements and how to dodge it.

Small tweaks to make Gas Valve Replacements safer and easier to use.

Timely gas valve replacements contribute to the safe operation of gas systems, reducing the risk of leaks or failures. Regular maintenance schedules and professional assessments are recommended to determine optimal timing for replacements. Interested parties should consider scheduling an inspection to evaluate their system's condition.